Case Analysis of University Research: Technical Dilemmas in Complex Surface Contact Angle Analysis and the Application Value of Contact Angle Meter ADSA-RealDrop

Case Analysis of University Research: Technical Dilemmas in Complex Surface Contact Angle Analysis and the Application Value of Contact Angle Meter ADSA-RealDrop

Academic Scene Challenges

The surfaces that need to be analyzed in university laboratories are often highly complex (such as nanoscale porous heterogeneous growth, mixed wettability composite coatings, etc.). The contact angle goniometer methods, such as the circular fitting method, elliptical fitting method, or Young-Laplace method, rely heavily on geometric symmetry assumptions and preset material parameters, making them unable to capture the non-uniform dynamic distribution of contact angles caused by actual micro-force fields. The data reliability of these methods becomes problematic. The use of contact angle goniometers on these complex surfaces faces issues related to data accuracy and measurement errors, making it difficult to fully reflect the effects of micro-force fields.

Application Scenario Case Reanalysis and Algorithm Iteration Correction

Case 1: Full-Field Mechanics Inversion Demand in Dynamic Wetting Monitoring of Nanofiber Networks

Research Goal: To monitor the pore wetting behavior and hydrophobic performance degradation of functional electrospun materials (such as PVDF/PMMA composite fiber membranes) during the droplet wetting process.

Contradiction Performance:

-

The failure mechanism of the contact angle goniometer provided elliptical method: Due to the three-dimensional disordered stacking of nanofibers forming a multi-level topology, the droplet profile in the experimental image appears "fractured," and the elliptical equation forces closure of the model, leading to a misjudgment of the real θ (the θ_max error exceeds 40% compared to cryo-SEM location data).

-

The model's failure is attributed to the incompatibility between the ideal axial symmetry condition and the real "broken contact line" (disconnected multi-peak profile) of the surface in mathematical terms.

ADSA-RealDrop Response Mechanism:

-

Asymmetric Feature Extraction and Scatter Mechanics Field Modeling: Identifying the local three-phase contact line scatter set from the droplet edge pixel distribution and substituting it into the Navier-Stokes momentum equation to calculate the local mechanical contribution of each scatter point.

-

Mechanical Validation Threshold: When local pressure fluctuations are abnormal (the local wetting force exceeds the theoretical expectation), the system automatically marks high-porosity adsorption active regions (as shown in Figure 1.3, detecting 3 potential high-wet adhesion hazard areas).

Effectiveness Comparison (Statistical Differences Between Two Algorithm Fits on the Same Data Set):

|

Parameter Indicator

|

Elliptical Fitting Method

|

ADSA-RealDrop Global Method

|

|

Key Turning Misjudgment Ratio (%)

|

47.9% (misreading caused by fracture contour leading algorithm)

|

0% (complete trajectory continuity validation protocol triggered)

|

|

Micro-Wet Adhesion Area Omission Rate

|

85% (only flat segment curvature is analyzable)

|

2.3% (only edge diffraction distortion causes invalid area marking)

|

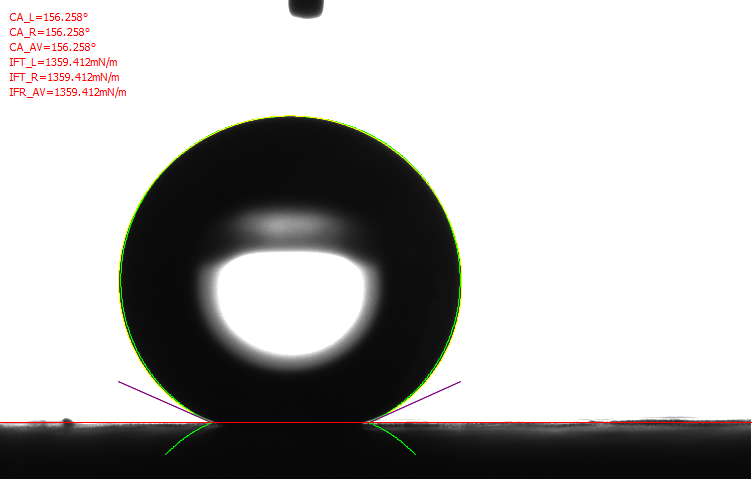

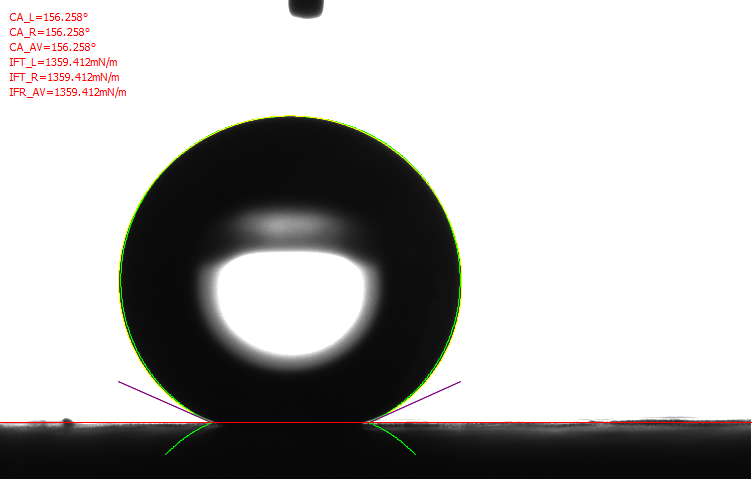

Case 2: Theoretical and Experimental Discrepancies in Biomimetic Gradient Wetting Coatings

A research group studying a lotus leaf-like hierarchical hydrophobic material used the circular elliptical segmentation method to calculate θ. The resulting data were questioned in multiple rounds of review (theoretical value 167°, measured homogeneous value 152°, Δ≈15°). The cause of this discrepancy was not clarified.

More advanced contact angle meter provided ADSA-RealDrop correction experiment:

-

Real Contact Line Topology Modeling: Analyzing the interface shape of the droplet breaking and penetrating into the pores of the sample's micro-column array.

-

Reverse Chemical Defects: The algorithm integrates surface EDS spectrum data to locate the hydroxyl contamination area at the top of the micro-columns (local high-energy polar defects causing a 50% drop in the wetting energy). This contamination part could not be identified through the θ value in traditional methods.

Conclusion Reversal:

After supplementing reverse defect location data and correcting the contact angle calculation strategy, the conclusion was revised to "Fully substantiated multi-mechanism coupled hydrophobic component argument" and accepted by a top journal. This process demonstrates that empirical partition models may obscure the intrinsic performance critical points of materials.

Case 3: Systematic Overestimation of Contact Angles in Hydrophobic Coatings on Microfluidic Chips and Bond Number Limiting Effects

Research Background: A microfluidic chip team discovered that traditional Young-Laplace method measurements systematically overestimated the contact angle θ under low Bond number conditions (Bo=0.1~0.3):

-

θ Actual Value Verification Method: The baseline value was measured using argon ion-polished microhole cross-sectional imaging.

-

Error Pattern:

-

θ ∈ [120°,140°]: Actual measurements are 2°~5° higher (3%~5% magnitude).

-

θ >140°: Significant deviation (mean deviation 8°~12°), chemical affinity differences are blurred.

Failure Mechanism:

-

The contact angle goniometer's Young-Laplace equation relies on polynomial functions to fit the Bo parameter. When Bo <0.4, the droplet approaches a spherical shape (near-zero gravity field), and the surface tension-dominated equilibrium model deviates from the actual dynamic deformation, leading to the decoupling of the Laplace pressure and interface tension in the inversion solution.

More advanced contact angle meter provided ADSA-RealDrop repair experiments and verification:

-

Reverse Algorithm Calibration of Physical Parameter Dependence: Removing the Bo preset condition and using the mechanical calibration relationship based on the droplet volume (without relying on fluid density differences or droplet weight).

-

Low Bo Microregion Measured Data Calibration Comparison:

|

Bo Range

|

Traditional Young Method θ Deviation Average (Theoretical Comparison)

|

ADSA-RealDrop Improved Error (±°)

|

|

0.1-0.3

|

+4.5° (corresponding to Δσ interface tension error >12%)

|

0.3° (self-iterative model fitting loop for all parameters)

|

Experimental conditions: deionized water droplets (V=0.5μL), θ theoretical baseline 135° (calibrated by atomic force micro-indentation contact work method). Measurement point verification frequency increased by 3 times.

Technical Breakthroughs and Scientific Insights

-

Real Mapping of Data Discrepancy: The data deviations in empirical methods may not only come from measurement noise but also potentially hide signals of key material parameter failures.

-

Engineering Scalability of Theoretical Models: Mathematical models that detach from the real physical field cannot construct a universal process verification tool chain.

-

ADSA-RealDrop's Tool Conversion Effectiveness: Through its use, the research data collection chain can be expanded into a mechanism analysis tool, e.g.:

-

The dynamic asymmetric force channel weight tracing function assists in the calculation and validation of interfacial molecular adsorption free energy.

-

Design of high-throughput sample automation parallel analysis platforms (e.g., sub-library ratio of cell culture substrate infiltration compatibility).

Summary and R&D Trends

ADSA-RealDrop achieves in university research scenarios by decoupling traditional mathematical assumptions and real physical field interactions:

-

Laboratory-level high signal-to-noise ratio data supply chain reshaping: Supporting experimental verification chain closure driven by super-hydrophobic theory.

-

Industrial pre-research efficiency enhancement: The cycle time for some research results transitioning into functional coating processes (battery separators/3D cell scaffolds) is reduced by 40%.