Overview of difference between KINO’s contact angle meter and other manufactory’s

Overview of difference between KINO’s contact angle meter and other manufactory’s

|

|

|

KINO

|

KRUSS

|

KSV

|

Ramehart

|

KYOWA

|

|

Model

Components

|

|

C602

|

DSA100E

standard component + PA3220 Tilting Base Assembly for DSA100 + EM3210 Electronic Module + DS3210 Single Direct Dosing System

|

Theta

standard component + T330 Motorized XYZ sample stage + C204A Tilting cradle

|

Model 590

|

DM901

Standard component + DM-SA01 sliding method kit

|

|

Appearance

|

|

|

|

|

|

|

|

1

|

Sample stage and its control system *1

|

X axis*2

|

Automatic, Motorized linear stage controlled by software with slide guide, travel range: 100mm, accuracy: 5um, resolution:0.1um

|

Automatic, common motion system controlled by software, travel range: 100mm

|

Automatic, controlled by software, travel range: 180mm, Resolution: 0.01mm

|

Manual, travel range is not mentioned

|

Automatic, controlled by software, travel range: 150mm

|

|

2

|

Y axis

|

Automatic, controlled by software, travel

range: 60mm, Resolution: 0.01mm, provide a long travel dovetail guide

for quick movement

|

Automatic, controlled by software, travel range: 75mm

|

|

3

|

Z axis*3

|

Manual, controlled by crossed-roller guide positioner with micrometer, travel range: 50mm, accuracy: 0.01mm

|

Manual, controlled by rack and pinion dovetail stage, travel range:40mm

|

Automatic, controlled by software, translating optical post holder, travel range: 30mm, Resolution: 0.01mm

|

translating optical post holder

|

Manual, Z-axis: 35 mm

Moving camera

|

|

4

|

Levelness adjustment*4

|

Dual-axes tilting stage with micrometer

|

N.A.

|

Simple screw adjusting structure

|

Simple screw adjusting structure

|

N.A.

|

|

5

|

Size of sample stage

|

100*100mm

|

105*105mm

|

75*75

|

51 x 76mm

|

150*150mm

|

|

6

|

Max sample size

|

Unlimited x 310 x 100 mm

|

Unlimited x 300 x 100 mm

|

W unlimited x L 180 x H 95mm

|

up to 300 x 300mm

|

150 mm x ∞, thickness 35mm, 400g max

|

|

7

|

Tilting stage *5 (For measurement of roll-off angle and advancing and receding contact angle)

|

Specially designed mechanical Structure: Rotating only Lens, sample stage and its control system.

|

Complete machine rotated

|

Complete machine rotated

|

Complete machine rotated

|

Complete machine rotated

|

|

8

|

Dosing system and it control system

|

Dosing system*6

|

Automatic direct single syringe pump

|

Automatic direct single syringe pump

|

Manual singe syringe pump or automatic syringe pump

|

automatic syringe pump

|

Automatic direct single syringe pump

|

|

9

|

Drop transferring*7

|

Automatic

Needle up and down

|

Automatic

Needle up and down

|

Automatic

Needle up and down

|

Manual

Needle up and down

|

Automatic, sample stage up and down

|

|

10

|

Positioning of needle X axis

|

Manual, controlled by crossed-roller guide positioner with micrometer, travel range: 12.5mm, accuracy: 0.01mm

|

N.A.

|

Not Mentioned

|

Not Mentioned

|

Not Mentioned

|

|

11

|

Focus distance adjustment

|

N.A.

|

Not Mentioned

|

Not Mentioned

|

Not Mentioned

|

|

12

|

Vision system

|

Camera*8

|

1/1.8" HD and high speed camera (Image

resolution:1280*1024, Speed: 60FPS

(1280*1024)-119FPS(640*512)-221FPS(320*256)-427FPS(800*120); USB3.0)

|

1/2" VGA camera, Image resolution: 780*580, speed: 61FPS (780×580)- 73FPS (780×480)-212FPS (780×120)- 311FPS(780×60);

IEEE1394b interface;

IEEE1394b PCI express card must be needed.

|

1/2" VGA camera, Image resolution: 640 x 480, Speed: 60 FPS (640*480)

IEEE1394b interface;

IEEE1394b PCI express card must be needed.

|

1/3" VGA camera, Image resolution: 768x494, 70FPS

IEEE1394a interface;

IEEE1394a PCI express card must be needed.

|

VGA camera, Standard camera with speed max. 60fps

|

|

13

|

Lens*9

|

Telecentric Lens

Field of view with 1/2" camera: 3.5 ... 22.8 mm diagonal. (about 0.5X)

|

Common zoom lens 0.5X

Field of view with 1/2" camera: 3.2 ... 22 mm diagonal. (about 0.5X)

|

Common zoom lens

Field of view with 1/2" camera: 2...12.8 mm diagonal. (about 1X)

|

Fixed focus lens

|

3 Step Zoom lens, field of view (width -6.6mm, 11.8mm, 17.0mm, about 8.25, 14.75,21.25mm diagonal) (about 0.24X, 0.18X)

|

|

14

|

Tilted angle of camera

|

Manual, controlled by micrometer

|

Manual, controlled by micrometer

|

N.A.

|

N.A.

|

N.A.

|

|

15

|

Background Light*9

|

parallel light background light

LED light with adjustable brightness

|

halogen illumination with adjustable brightness

diffuse light

|

LED light with adjustable brightness,

diffuse light

|

Variable Fiber Optic Illuminator

|

tungsten lamp with adjustable brightness

diffuse light

|

|

16

|

Software

|

Calculating method of contact angle

Auto calculating

|

θ/2

(WH), circle fitting , ellipse fitting , curve ruler (tangent fitting ),

Spline curve-fitting , and Young-Laplace equation fitting (RealDrop)

|

WH method, Tangent method (composite curve “y=a+bx+cx0,5+d/lnx+e/x2“ used only in Kruss’s software, ellipse fitting), Circle fitting, Young-Laplace equation fitting (>30°)

|

Circular fit, Polynomial fit, Young-Laplace

|

Circle method, extrapolated Secant method, Line method, full Drop method (Young-Laplace equation fitting) (>45°)

|

θ/2 method, Circle fitting, Ellipse fitting, Tangent method

|

|

17

|

Automatic tracking

|

Yes

|

Yes

|

Yes

|

Not mentioned

|

Yes

|

|

18

|

Recalculate contact angle by manual if automatic calculation is failure due to quality of image is poor.

|

Yes

Includes all methods

|

No

|

No

|

No

|

Not mentioned

|

|

19

|

Method of Young-Laplace equation fitting * 10

|

Based on ADSA and RealDrop method

|

B. Song’s method

Young-Laplace equation fitting based on select plane method

|

Jennings’s method

Young-Laplace equation fitting method based on rotational discrim ination method (1988, angmuir,1988, page 9592)

|

Hansen’s method

Young-Laplace equation fitting based on select plane method

|

Algorithm of Young-Laplace and ds/de methods (simplified select plane method)

|

|

20

|

Data management

|

Managing measured values and captured

images. one-to-one correspondence of data and drop images; backup,

compression, and exporting to Excel files; measured values and

curve-fitting results can all be saved into exported image.

|

measure, store and

report measured contact angle values

|

Managing measured values and videos.

|

Managing only measured values.

|

Managing only measured values.

|

|

21

|

Method for calculating surface free energy (SFE)

|

12kinds

Equation of State (Neumann et al.),

Good-Girifalco, Owen-Wendt-Rabel, Simple Fowkes, Extended Fowkes, WU

method 1-2, Schultz method 1-2, Acid-base (Van OSS & Good), Jhu, and

Zizman Plot (critical surface tension) method, Chibowski method

|

9 kinds

Equation

of state, Fowkes, Fowkes

(Extended), Owen-

Wendt-

Rabel-

Kaelble, Acid-Base, Wu1, Schultz-1 /2, Zisman

|

8 kinds

Zisman Plot, OWRK/Extended Fowkes, van Oss Acid-Base, Wu,

Neumann’s Equation of State, Schultz 1 and 2

|

7 kinds

Acid – Base tool, geometric mean (Owens), Rabel, Equation of stage (Neumann), Zisman’s Plot Tool, Schultz 1, 2

|

4 kinds

Geometric mean, Harmonic mean, acid-base, Zisman

|

|

22

|

Liquid database

|

300 kinds liquid and about 800 data

|

50 kinds liquid and 102 data

|

yes

|

Yes

|

Not mentioned

|

|

23

|

wetting envelope

|

Yes

3 methods

|

Yes

1 methods

|

No

|

No

|

No

|

|

24

|

Calculating thermodynamics intrinsic contact angle

|

Yes

|

No

|

No

|

No

|

No

|

|

25

|

Curve surface base line

|

Curve ruler method: any shape surface

|

Circle fitting method:

|

|

|

Curve surface base line

|

|

26

|

Auto Base line

|

Yes

|

Yes

|

Yes

|

No

|

Yes

|

|

27

|

Software triggering technology

|

Yes

|

yes

|

Yes

|

Yes

|

Yes

|

|

28

|

Image Sharpness Measurement

|

Yes

|

Yes

|

Yes

|

NO

|

NO

|

|

29

|

Auto threshold

|

3 methods

|

No

|

No

|

No

|

No

|

|

30

|

Function of export to AVI after deleting some images.

|

yes

|

No,

just record

|

No,

just record

|

No,

just record

|

No,

just record

|

|

31

|

Writing fitting curve to captured image

|

Yes

|

No

|

No

|

No

|

No

|

|

32

|

Export to EXCEL files and BMP format picture

|

Yes

|

Only Value export to EXCEL or TXT files

Images should save or record into video.

|

Not mentioned

|

Only Value export to EXCEL

|

Only Value export to EXCEL

|

|

33

|

Control hardware such as dosing and positioning

|

Yes

|

Yes

|

Yes

|

Yes

|

Yes

|

|

Note:

1, 2, 3 Control of sample stage along XY axis is

used for measuring contact angle of different position on sample

surface. And, control of sample stage along Z axis is used for measuring

sample with different thickness. KINO is only manufactory of contact

angle meter that adopts motorized linear stage or manual positioner for

motion control system. By comparison, contact angle meter made by other

factory always uses common adjustment mechanism such as “dovetail stage”

or just one optical bench with holder unit and height adjustable rod

stand. (Note: these is always used for quick and long travel range

adjustment that need no accuracy.)

For more information of them, visit https://www.newport.com/Products/5465115/1033/nav.aspx or http://www.sigma-koki.com.

KINO’s contact angle meter adopts such motion control system as this

manufactory’s and accords with its design accuracy. You can find

difference such as load capacity and travel accuracy between rack and

pinion dovetail stage, translating optical post holder and

crossed-roller guide positioner with micrometer. It is shown that

crossed-roller guide positioner with micrometer is most suitable for

vertical position. Motorized linear stage controlled by software with

slide guide provide more stable and smooth movement and positioning of

drop.

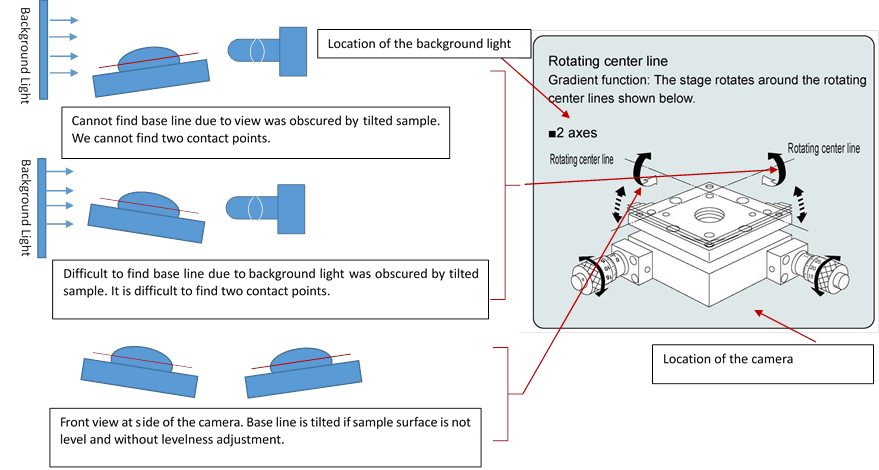

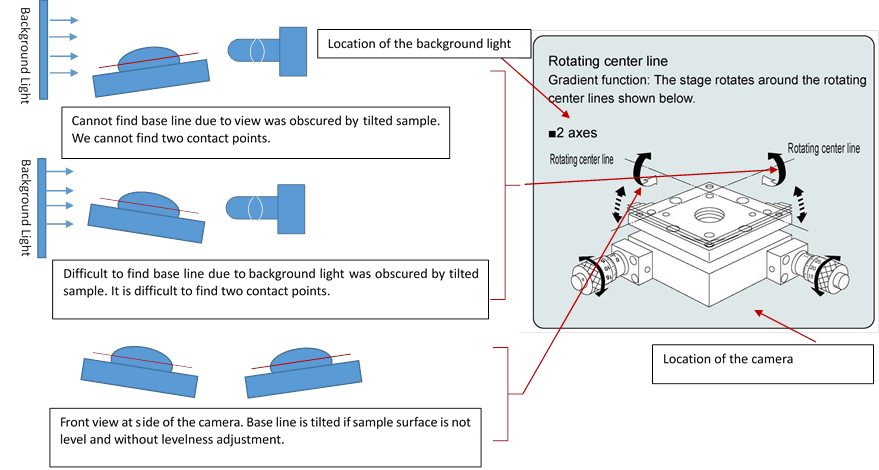

4, Level adjustment of sample stage except adjusting

complete machine by four adjustable legs is most important. For

example, after you adjusted levelness of sample stage at first, when you

measure sample with poor level surface, it is more difficult to get

good base line and obtain two contact points. As shown below:

o:spid="_x0000_s1084" strokecolor="#c00000" strokeweight=".5pt"

style="position: absolute; width: 3048px; height: 9620px; visibility:

visible; top: 35909px; left: 46863px; mso-wrap-style: square;

v-text-anchor: middle; rotation: 180" type="#_x0000_t87">5,

Tilting system for measurement of roll-off angle of KINO’s contact

angle meter adopts motorized rotation stage with very low backlash, low

wobble (about 40urad) and high absolute accuracy (about 0.01°)

. KINO exclusively provides you specially designed mechanical Structure

(Rotating only Lens, sample stage and its control system) instead of

rotating complete machine. Accuracy and backlash of latter is very poor

due to control complete machine is very difficultly.

6, We suggest our customer to choose direct single

syringe pump instead of syringe pump with tee-junction because latter is

difficult to clean and easily lead to cross contamination e.g. water

for measurement of contact angle is contaminated by oil.

|

|

|

|

direct single syringe pump

- Advantage: Easy to clean and remove syringe, High precision, pollution-free.

- Shortcoming: inconvenient to measure contact angle with multiple liquid.

|

syringe pump with 3 port value

- Advantage: Difficult to clean pump, value and tube, easily lead to cross contamination, cannot dosing liquid with viscosity

- Shortcoming: convenient to measure contact angle with multiple liquid when equipped with multi-channel pump.

|

7, usually, there are two drop transferring method-

by move needle down and then up or by move sample stage upside and

downside. We prefer first method due to we can easily control the base

line of contact angle (it remains at same position) by first one. By

second one, base line is bound to move because sample surface moved

during this process. And for measuring contact angle of

super-hydrophobic surface, movement of needle must be very carefully

because it is difficult to transfer drop to this surface. So, we adopt

positioner stage with micrometer or controlled by step motor to get high

precision of control.

8, Interface of Camera that USA KINO adopted is

USB2.0 or USB3.0, which is more mutually compatible with PC than

IEEE1394a or IEEE1394b. Most suitable resolution of camera for contact

angle meter is about 130M, and 40M is most common resolution that used.

Visit http://www.uskino.com/news/50.html to find more information about this topic.

9, Telecentric Lens and Parallel light Background

light are most suitable for contact angle measurement for the following

reasons. With them, we can benefit highest precision measurement values

at sub-pixel resolution.

(1) Magnification Constancy

Common lenses give different magnifications at

different conjugates: as such, when the object is displaced, the size of

its image changes almost proportionally with the object-to-lens

distance. This is something anybody can easily experience in everyday

life, for example when taking pictures with a camera equipped with a

standard photographic lens.

Fig.

1: a standard lens generates different size images when changing the

object-to-lens distance (indicated as ”s” in the drawing). On the other

hand, objects of different sizes would look as if they had the same

dimensions, provided they subtend the same viewing angle.

With

telecentric lenses the image size is left unchanged with object

displacement, provided the objectstays within a certain range often

referred to as “depth of field” or “telecentric range”. This is due to

the particular path of the rays within the optical system: only ray

cones whose barycentric ray (or “principal ray”) is parallel to the

opto-mechanical main axis are collected by the objective. For this

reason, the front lens diameter must be at least as large as the object

field diagonal. This optical behaviour is obtained by positioning the

stop aperture exactly on the focal plane of the front optical group: the

incoming rays aim at the entrance pupil which appears as being

virtually placed at the infinity. The name “telecentric” derives from

the words “tele” (which means “far” in ancient Greek) and “centre” which

accounts for the pupil aperture, the actual centre of an optical

system.

Fig. 2: in a telecentric system rays get into the optics only with an almost parallel-to-the-axis path.

(2) Low Distortion

Distortion is one of the worst problems limiting

measurement accuracy: even the best performing optics are affected by

some grade of distortion, while often even a single pixel of difference

between the real image and the expected image could be critical.

Distortion is simply defined as the percentage

difference between the distance of an image point from the image center

and the same distance as it would be measured in a distortion-free

image; it can be thought of as a deviation between the imaged and the

real dimensions of an object. For instance, if a point of an image is

198 pixels distant from the center, while a distance of 200 pixels would

be expected in absence of distortion, the radial distortion, at that

point, would be

Distortion = (198-200)/200 = -2/200 = 1%

Fig.3: “pincushion” type distortion “barrel” type distortion

Positive radial distortion is also called

“pincushion” distortion, negative radial distortion is called “barrel”

distortion: note that the distortion depends on the radial position and

can also change of sign. Distortion can be also viewed as a 2D

geometrical transformation of the real world into the virtual space

created by the lens; as this transformation is not perfectly linear but

is approaching 2nd or 3rd degree polynomials, the image becomes slightly

stretched and deformed.

Common optics show distortion values ranging from

some percent to some tens percent, making precise measurement really

difficult; things get even worse when non-telecentric lenses are used.

Since most machine vision optics have originally been developed for

video-surveillance or photography applications, relevant distortion

values have usually been considered acceptable, as the human eye can

compensate distortion errors up to 1-2%. In some cases, like in fish-eye

lenses or webcam-style lenses, distortion is intentionally introduced

to make the lens work on large angles also providing an even

illumination of the detector (in these cases distortion is helpful in

reducing cosine-to-the-fourth law effects).

High quality telecentric lenses normally show a very

low distortion degree, in the range of 0,1%; although this amount seems

to be very small it would actually result into measurement errors

approaching the size of one pixel of an high resolution camera. For this

reason, in most applications, distortion has to be software calibrated:

a precise pattern (whose geometrical accuracy must be at least ten

times better than the needed measurement accuracy) is placed at the

center of the field depth; distortion is then computed at several image

points and, based on these data, the software algorithm transforms the

native image into a distortion-free image. Few people know that the

distortion also depends upon the distance of the object, not only upon

the optics itself; for this reason it is very important

Few people know that the distortion also depends

upon the distance of the object, not only upon the optics itself; for

this reason it is very important that the nominal working distance is

strictly respected.

A fine perpendicular alignment between the lens and

the inspected object is recommended in order to avoid non-axially

symmetric distortion effects. Trapezoidal distortion (also known as

“keystone” or “thin prism” effect) is another important parameter to be

minimized in an optical inspection system as it is asymmetric and very

difficult to software calibrate. Lens focusing mechanism can also

introduce some symmetric or non-symmetric distortion effect because of

mechanical play or optical element decentering.

Fig. 4: on the left an image of a distortion pattern

taken with a telecentric lens, where no radial or trapezoidal

distortion is present. In the middle the image of the same pattern

showing strong radial distortion. On the right an example of trapezoidal

distortion.

(3) Perspective Errors limitation

When using common optics to image 3D objects (non

completely flat objects) far objects will look smaller than close

objects. As a consequence, when objects like a cylindrical cavity are

imaged, the top and the bottom crown edges will appear to be concentric

although the two circles are perfectly identical.

On the contrary, by means of a telecentric lens, the

bottom crown edge will disappear because the two crown edges are

perfectly overlapping.

Fig. 5: Common optics showing significant image

perspective error (on the left). A telecentric lens is able to cancel

any perspective effect (on the right).

This effect is

due to the specific path of the rays: in the case of common optics, any

geometric information that is “parallel” to the main optical axis also

shows a component on the detector plane direction, while in a

telecentric lens this perpendicular component is totally absent.

One could describe a common lens as a mathematical

function building a correspondence between the 3-dimensional object

space and the 2-dimensional detector (image) space while a telecentric

would build a 2D-2D correspondance as would not display an object’s third dimension thus making it the perfect component for profile imaging and measurement.

Fig. 6: Common optics (left) project longitudinal geometrical information onto the detector, while telecentric lenses are not.

(4) Good image resolution

Image resolution is decribed by CTF (contrast

transfer function) which quantifies the contrast ratio at a given

spatial frequency on the camera detector plane, expressed in lp/mm (line

pairs per millimeter).

Fig. 7: good and bad contrast achieved with optics of varying CTF looking at a standard USAF test pattern.

Quite often, machine vision integrators tend to

combine cameras having tons of small pixels with cheap, poor resolution

lenses, resulting in blurred images; the resolution provided by

telecentric lenses is compatible with very small pixel sizes and high

resolution cameras thus increasing the measurement resolution.

(5) No edge position uncertainty

When common back lighting an object it can often be difficult to determine the exact position of its edges.

This can happen because the bright pixels in the

background tend to overlap with the dark pixels at the object edges.

Moreover, if the object is highly 3D-shaped, also a border effect could

furtherly limit the measurement precision; as shown in the following

drawing, rays grazing the object edges at certain incidence angles could

be reflected by the surface, but still be collected by the lens.

The lens would then see those rays as if they were

coming from behind the object; as a result, slices of the image could

disappear, thus making the measurement very much imprecise and unstable.

Fig. 8: Border effects in a common imaging lens are strongly reduced by means of a telecentric lens

This effect can be efficiently limited by means of a

telecentric lens: if the pupil aperture is small enough, the only

reflected rays which could enter the lens would be those nearly parallel

to the optical main axis.

As these rays are affected by very small deflection,

the reflection from the object surface doesn’t jeopardize the

measurement accuracy.

To get rid of such issues, Parallel light Background light (also

called “collimated” or “telecentric”) illuminators can be interfaced to

telecentric lenses, taking care of matching the lens aperture and FOV

with the collimated source divergence. With this option, all the light

coming out of the illuminator is collected by the lens and delivered

onto the detector, allowing extremely high signal-to-noise ratios and

incredibly low exposure times. On the other hand, only “expected” rays

come into the imaging lens so that no problems occur at the borders.

Fig. 9: Parallel light Background light (Collimated light, telecentric) illumination projects only the expected rays into the imaging system.

We captured some images use using 2 different

combinations of lens and background (one is common lens and diffused

background light as used in general contact angle measurement

instrument, another is used telecentric lens and Parallel light

Background light)

Fig. 10: Image of pendant drop used Parallel light

Background light and telecentric lens. We can find little change range

of sharpness at image edge when zooming it about 1500X.

Fig. 11: Image of pendant drop used common

Background light and lens. We can find more change range of sharpness at

image edge when zooming it about 1500X.

Fig. 12: Image of sessile drop with little change range of sharpness used Parallel light Background light and telecentric lens.

Fig. 13: Image of sessile drop with more change range of sharpness used common Background light and lens.

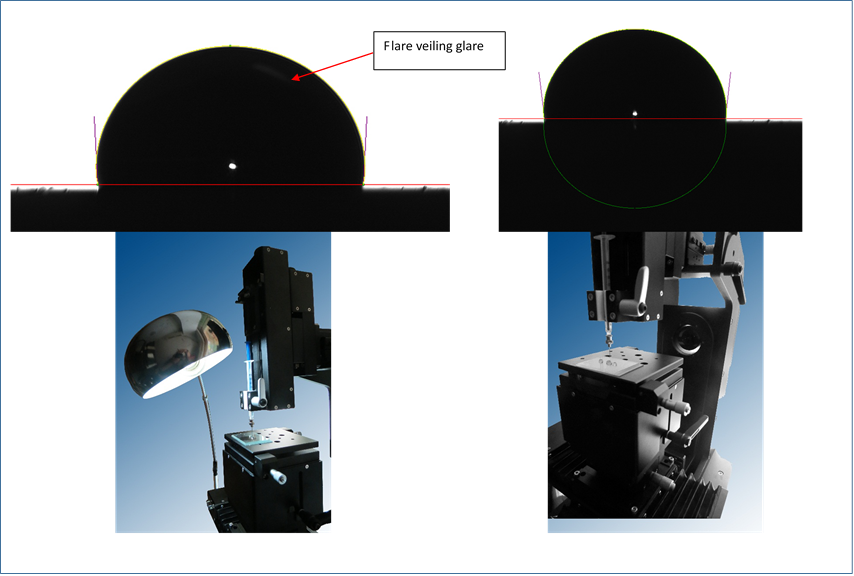

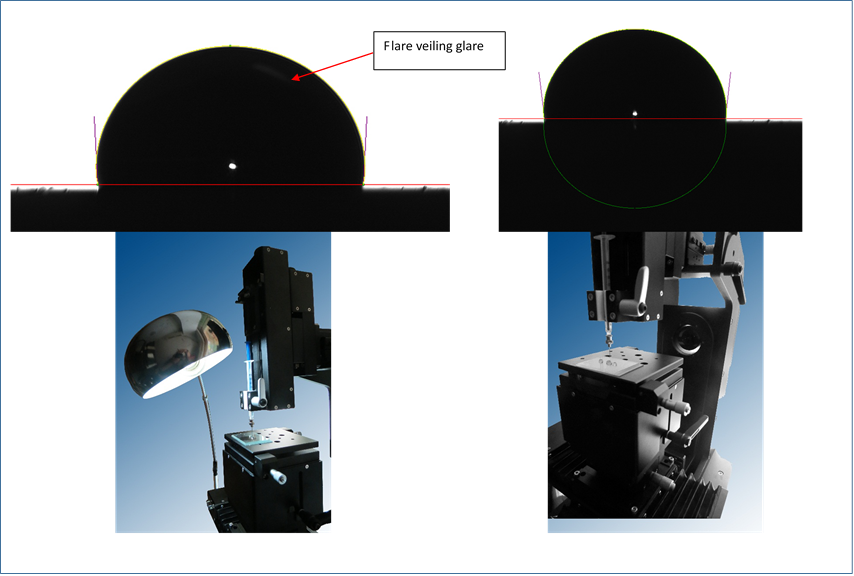

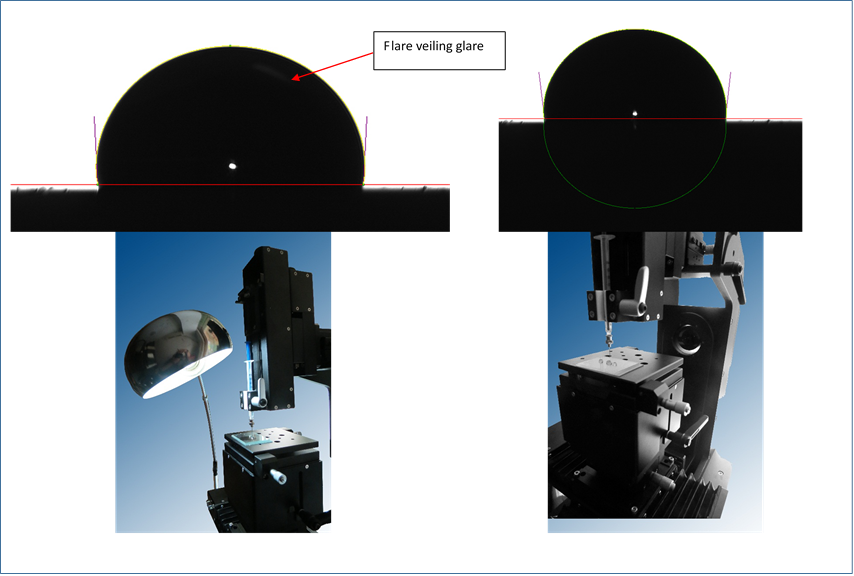

(5) Not disturbed by flare veiling glare

Flare veiling glare will not disturb image capture process.